Cannabis products undergo gradual degradation processes that fundamentally differ from traditional food spoilage patterns. Unlike perishable foods that develop harmful bacteria or toxins, cannabis experiences a systematic breakdown of its active compounds, particularly cannabinoids and terpenes, which results in diminished potency, altered flavor profiles, and reduced therapeutic efficacy. Understanding these degradation mechanisms enables consumers to implement proper storage protocols that preserve product integrity and maximize investment returns.

The degradation timeline for cannabis products follows predictable patterns based on environmental conditions and storage methodologies. Properly stored cannabis flower maintains optimal potency and sensory characteristics for approximately six to twelve months, with measurable quality decline occurring thereafter. Research indicates that THC concentration decreases by approximately sixteen percent after one year of storage, twenty-six percent after two years, thirty-four percent after three years, and forty-one percent after four years when maintained under standard conditions.

Understanding Cannabis Degradation Mechanisms

Cannabis degradation occurs through multiple simultaneous processes that affect different product components at varying rates. Cannabinoid oxidation represents the primary mechanism responsible for potency loss, with THC molecules converting to CBN (cannabinol) when exposed to oxygen, light, and elevated temperatures. This conversion process reduces psychoactive effects while potentially increasing sedative properties, fundamentally altering the intended user experience.

Terpene volatilization constitutes another critical degradation pathway that significantly impacts flavor and aroma characteristics. These aromatic compounds possess lower boiling points than cannabinoids, making them particularly susceptible to evaporation under improper storage conditions. Temperature fluctuations, inadequate container sealing, and extended exposure periods accelerate terpene loss, resulting in diminished sensory appeal and potential therapeutic benefits associated with the entourage effect.

Moisture content fluctuations present additional challenges for long-term cannabis storage. Excessive humidity levels promote mold and mildew development, creating serious health hazards and rendering products unsafe for consumption. Conversely, insufficient humidity causes over-drying, which increases trichome brittleness and accelerates terpene evaporation while creating harsh smoking experiences.

Optimal Environmental Conditions for Cannabis Storage

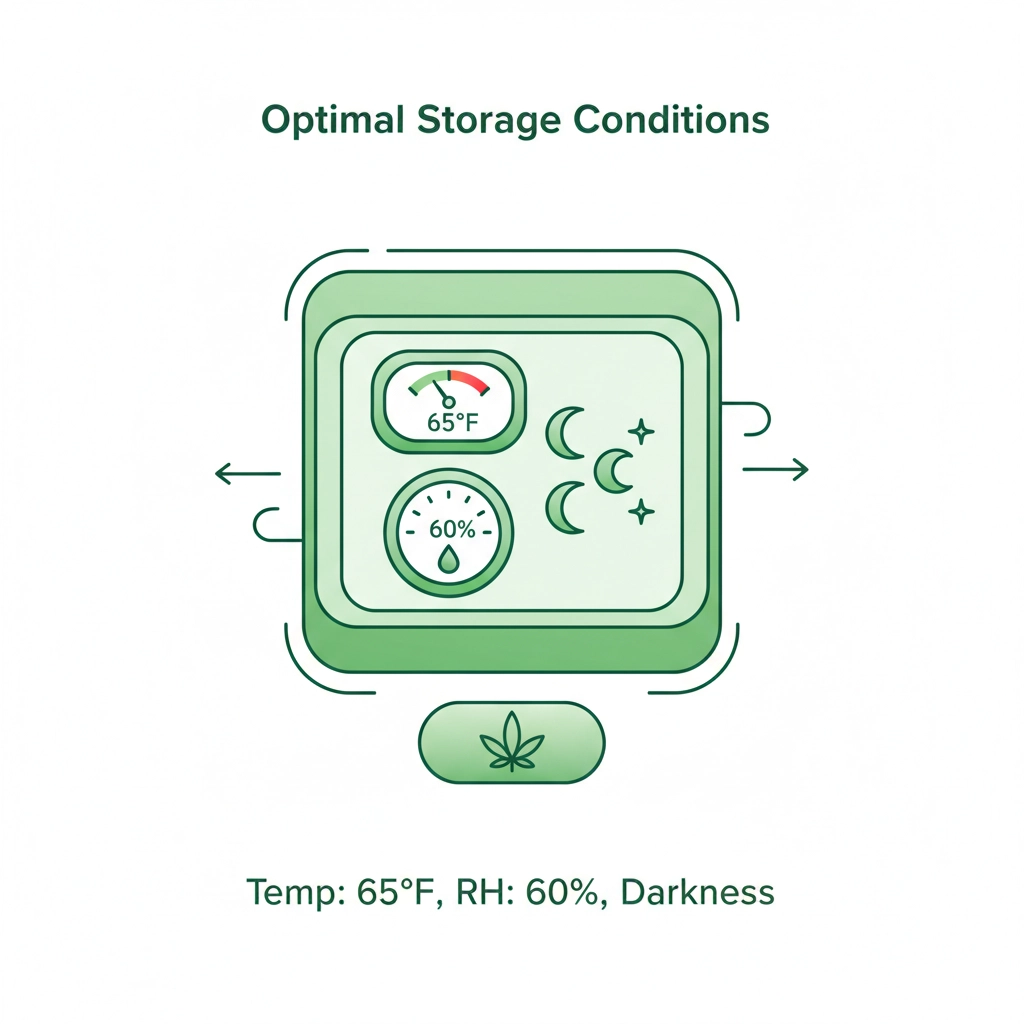

Temperature regulation forms the foundation of effective cannabis preservation strategies. Maintaining storage environments between 60-70°F (15-21°C) minimizes chemical degradation processes while preventing condensation formation that could promote microbial growth. Temperature consistency proves equally important, as fluctuations create expansion and contraction cycles that compromise container seals and increase oxygen exposure.

Humidity control requires precise management within the 59-63% relative humidity range to balance preservation needs with contamination prevention. This specific range maintains optimal moisture content for preserving trichome integrity while inhibiting mold development. Digital hygrometers provide accurate monitoring capabilities, enabling users to implement corrective measures before degradation occurs.

Light exposure elimination represents a non-negotiable requirement for proper cannabis storage. Ultraviolet radiation catalyzes cannabinoid degradation through photochemical reactions that irreversibly alter molecular structures. Dark storage environments, achieved through opaque containers and interior storage locations, effectively prevent light-induced deterioration while maintaining product stability over extended periods.

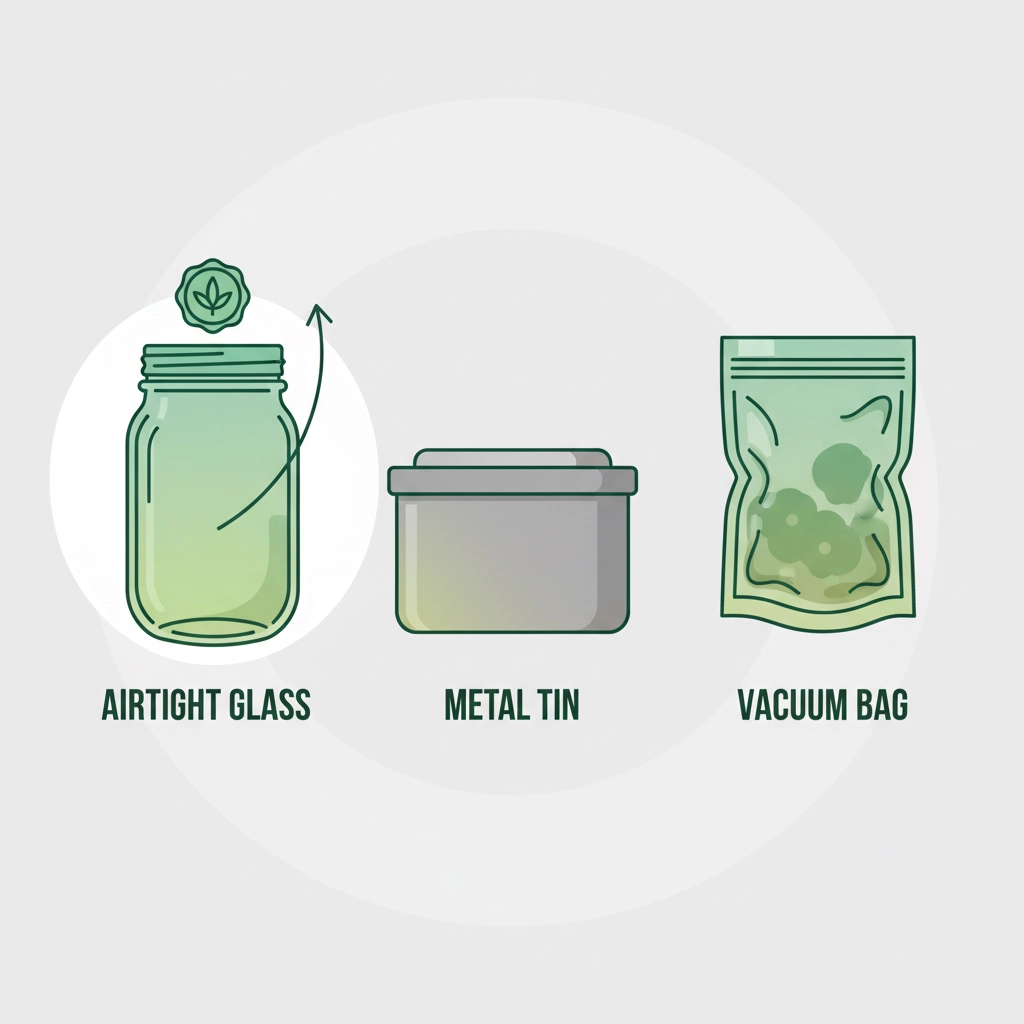

Air exposure minimization requires implementing airtight storage solutions that prevent oxidation processes. Vacuum-sealed containers offer superior protection by removing oxygen that would otherwise facilitate degradation reactions. Glass containers with reliable sealing mechanisms provide excellent alternatives while allowing visual inspection without compromising storage integrity.

Container Selection and Storage Infrastructure

Glass storage containers provide optimal protection for cannabis products due to their non-reactive properties, superior sealing capabilities, and resistance to temperature fluctuations. Mason jars with new lids offer cost-effective solutions for most consumers, while specialized cannabis storage containers incorporate humidity control systems and UV protection features for enhanced preservation.

Metal containers, particularly those constructed from food-grade materials, deliver excellent protection against light exposure while maintaining airtight seals. However, temperature sensitivity requires careful consideration, as metal conducts heat more readily than glass, potentially creating temperature fluctuations in variable environments.

Plastic storage solutions generally prove inadequate for long-term cannabis preservation due to their porous nature and potential for chemical interactions. While suitable for short-term storage, plastic containers allow gradual air exchange and may absorb or release compounds that affect product quality over time.

Product-Specific Storage Recommendations

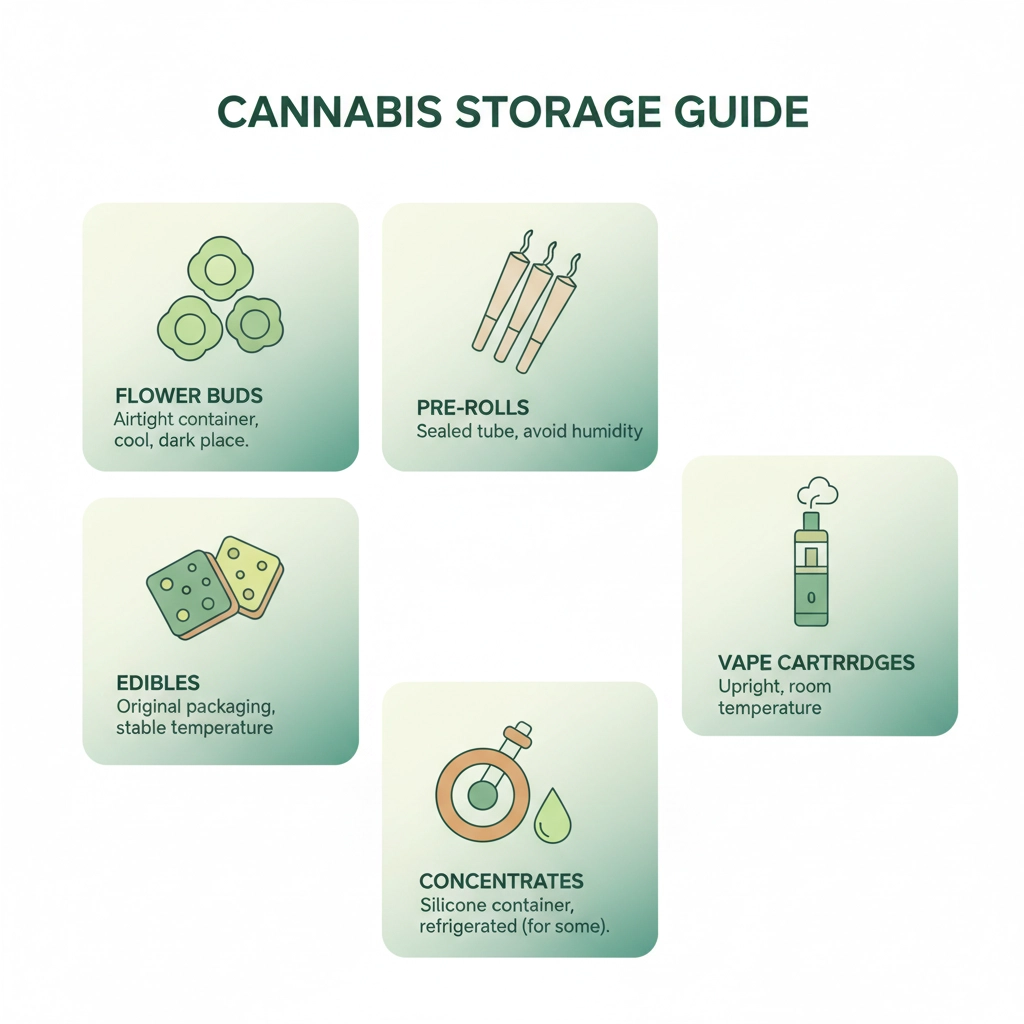

Cannabis flower requires specialized handling due to its delicate trichome structures and high terpene concentrations. Whole bud storage preserves quality longer than ground material, as grinding increases surface area exposure to degradation factors. Individual strain separation prevents cross-contamination of flavors and maintains distinct terpene profiles for each variety.

Pre-rolled products demonstrate accelerated degradation rates compared to whole flower due to increased surface area exposure and potential air pockets within the rolled structure. Consuming pre-rolls within three to six months of purchase ensures optimal flavor and potency retention while minimizing harsh smoking characteristics associated with aged material.

Edible products follow different preservation principles based on their carrier materials and manufacturing processes. Cannabis-infused baked goods typically maintain potency longer than fresh products but require protection from temperature extremes and humidity fluctuations. Gummies and hard candies demonstrate superior shelf stability due to their sugar content and moisture-resistant properties.

Vape cartridges require protection from temperature extremes and light exposure to preserve both cannabinoid potency and flavor integrity. Storage in original packaging within temperature-controlled environments maximizes product longevity while preventing hardware degradation that could affect functionality.

Concentrates and extracts demonstrate varying stability based on their extraction methods and post-processing treatments. Shatter and wax products require minimal light and air exposure, while live resin and sauce products benefit from refrigerated storage to preserve volatile terpene compounds.

Safety Assessment and Quality Indicators

Visual inspection provides the primary method for identifying compromised cannabis products. Mold growth appears as white, gray, or colored fuzzy patches on flower surfaces, while properly stored cannabis maintains consistent green coloration with minimal browning. Excessive dryness manifests through brittle textures and crumbling trichomes that indicate significant degradation.

Aromatic evaluation offers additional quality assessment capabilities. Fresh cannabis displays distinct terpene profiles characteristic of specific strains, while degraded products emit musty, stale, or hay-like odors indicating chemical breakdown or contamination. Any ammonia or chemical odors suggest serious contamination requiring immediate disposal.

Texture analysis reveals storage condition effects on product integrity. Properly preserved flower maintains slight moisture content with springy, non-brittle textures, while over-dried cannabis crumbles easily and produces harsh smoke. Excessive moisture creates sticky textures that may indicate humidity control failures and potential mold development.

Warning Signs and Safety Protocols

Mold contamination represents the most serious safety concern associated with aged cannabis products. Consuming moldy cannabis can cause respiratory irritation, allergic reactions, and potentially serious health complications for immunocompromised individuals. Any visible mold growth, regardless of extent, necessitates complete product disposal without attempted remediation.

Color changes beyond normal browning indicate significant degradation or contamination issues. While slight browning represents natural aging, dramatic color shifts to yellow, gray, or unusual hues suggest improper storage or contamination. Products displaying abnormal coloration require careful evaluation and potential disposal to ensure consumer safety.

Texture anomalies such as excessive moisture, sliminess, or unusual brittleness indicate storage failures that may compromise product safety. Overly moist products risk mold development even without visible signs, while extremely brittle material may have lost significant therapeutic compounds through degradation.

Implementation of Groth Industries Storage Standards

Implementing comprehensive storage protocols requires systematic attention to environmental controls, container selection, and monitoring procedures. Regular inspection schedules enable early detection of degradation signs while allowing corrective actions before complete product loss. Documentation of storage conditions and product acquisition dates facilitates rotation systems that ensure consumption of older products before significant quality decline.

Investment in proper storage infrastructure, including hygrometers, thermometers, and quality containers, provides long-term cost savings through reduced product waste and maintained potency levels. These initial expenses prove economical when compared to frequent product replacement costs associated with improper storage practices.

Consumer education regarding proper storage techniques empowers individuals to maximize their cannabis investments while ensuring safety and quality standards. Understanding degradation mechanisms and implementing appropriate countermeasures enables informed decision-making regarding product selection, storage duration, and consumption timing.

Have you evaluated your current cannabis storage methods to ensure optimal product preservation and safety compliance?